concrete mixing pump

The concrete mixer with pump adds drum mixer to the trailer pump, which integrates concrete mixing and pumping functions into one. There are many types of concrete mixer pumps available.

Electric model --

Capacity : 40 cubic meter per hour

Power : 55.55kw

Max pressure : 10Mpa

Maximum conveying distance Vertical/horizontal : 120/500m

Diesel power model --

Power : 84kw

Engine : Weichai brand

Max pressure : 10Mpa

Maximum conveying distance Vertical/horizontal :150/600m

The loader feeds the sand, stone, cement and other materials into the hopper and controls the hopper loading with the remote control. The mixed concrete is directly discharged into the pumping hopper and pumped to the destination through the pumping system. The whole operation is quite simple. Moreover, the concrete mixer pump also has the characteristics with low labor intensity, small investment and high return. Therefore, a reliable and reputable concrete mixer pump manufacturer is very important for your investment.

Systems & main parts details

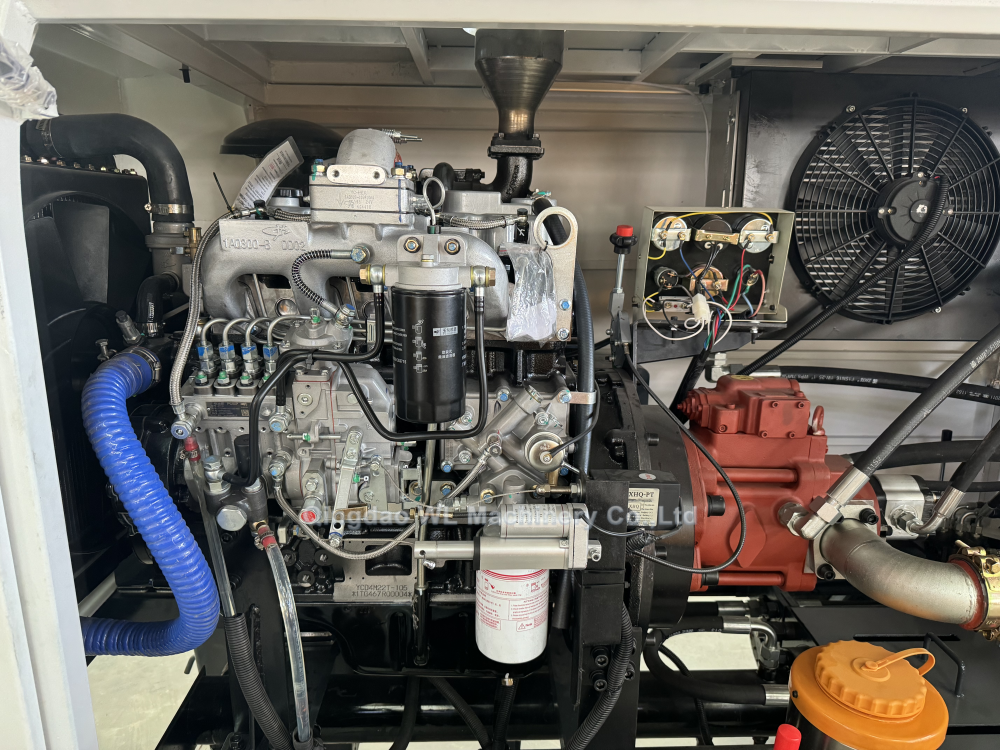

Power system

The diesel engine with China top level Weichai brand, we can also equip with Cummins brand diesel engine.

Main pumping system

We use the original imported main oil pump is Kawasaki brand , can also choose Rexroth main oil pump. Open loop for hydraulic oil system. Reliable main oil pump and concrete cylinder.

Distribution system

Adopt brand swing cylinder and S valve. The glass plate and cutting ring are made of special wear-resistant material.

Mixing system

Adopt China Top 1 mixing motor. Wear resistant mixing blades and mixing shaft. The hardness of the left and right half shaft can reach to HB250-280.

Cooling and filtering device

The filtering accuracy of the main pump suction oil filter is 100μm. Adopt high-quality cooler used for aeronautic.

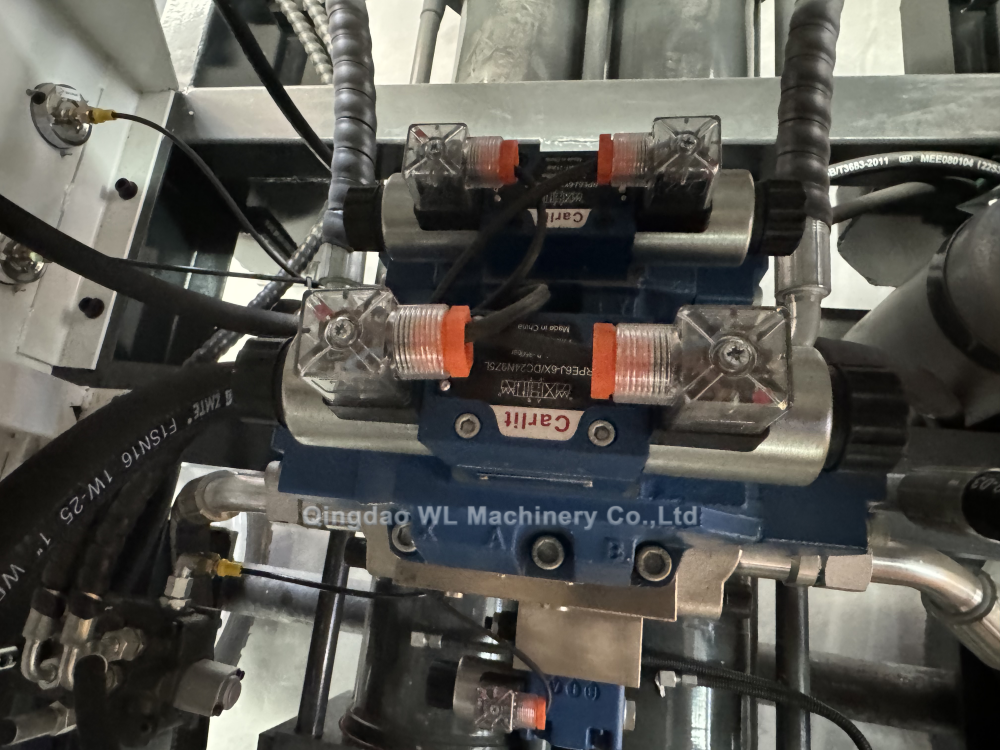

Hydraulic pipe and valves

Adopt Italy Manuli oil hose and Taiwan Yuken hydraulic control valve.

Electrical control system

We have equipped the conrtrol unit with German Siemens PLC, and the electrical parts use Schneider and Omron international brand.

Mixing drum

450L big mixing volume. Adopt 250 thicken channel steel, integrated type, which makes the whole structure very stable. Double hydraulic motors make sure that the driving speed is much faster and the mixing efficiency is much higher.

Pumping pipes

Concrete mixer and pumps are equipped with a complete range of pipes to meet the needs of our customers in different working conditions.

|

|

|

|

The advantages of our concrete mixing pump

1.Our concrete mixer and pumping machine is equipped with hydraulic oil tank that can be pickling and phosphating treatment of steel pipe. Moreover, the hose and valve block has a special cleaning oil tank.

2.The diesel cleaning port is first treated with high temperature, and then blown with a pressure air pump to ensure that no impurities are left. This really ensures that the oil quality of the hydraulic oil inside the system is clean, the equipment failure rate is lower, and the service life of the system is longer.

3.Before delivery, the workers debug the cement mixer with pump, and pump water for 8 hours, and divide it into three sections: high, medium and low pressure to test the pressure to ensure the stable operation of the whole machine.

4.Our mobile concrete mixer with pump is equipped with an energy storage device and a current compensator, which has a certain compensation effect when the voltage and current are unstable.

5.The pumping pipes are seamless high-pressure pipes. The diameter of the pipe is 125mm and the thickness is 4.5mm (of which the elbow is 5mm). Equipped with C-type quick pipe clamp, it is easy to install and disassemble, save time and improve work efficiency.

The advantages of our service :

Equipment free warranty period of 14 months : Our portable concrete mixer pump not only have wear and tear parts and also provide 14months warranty .

Local service network, timely supply of wearing parts : We will establishment of local after-sales service network and timely supply of wearing parts.

Product shipping : On-time delivery and deliver the concrete mixer with pump for sale to the customer's designated port.

Engineer guides installation : After-sales engineers are ready to guide various problems in the process of installation and use.

Customized one-to-one service : Technical staff provide customers with equipment selection, technical comparison and one-to-one service.

The Technical Parameters of electric model concrete pump with mixer :

|

Items |

unit |

Parameter |

|

|

Whole performance of machine |

Max. theo. concrete output |

m3/h |

40 |

|

|

Feeding Capacity |

m3 |

0.56 |

|

|

Discharging Capacity |

m3 |

0.45 |

|

|

Max. concrete pumping pressure |

MPa |

10 |

|

|

Distribution valve type |

/ |

S Pipe Valve |

|

|

Concrete cylinder diameter×stroke |

mm |

Ф180×1000 |

|

|

Hopper capacity |

L |

400 |

|

|

Outlet diameter |

mm |

Ф150 |

|

Power system |

Diesel engine model |

/ |

Huadong brand |

|

|

Electrical engineering power |

kW |

76 |

|

|

Rotate speed |

r/min |

2200 |

|

|

Winding motor |

/ |

Hydraulic Motor |

|

|

Stir the motor |

/ |

|

|

|

Water pump motor |

/ |

|

|

Hydraulic system |

Circuit type |

/ |

Open circuit |

|

|

Pumping system pressure |

MPa |

32 |

|

|

Mixing system pressure |

MPa |

6 |

|

|

Capacity of oil tank |

L |

350 |

|

Other parameters |

Max. aggregate diameter |

mm |

40-50 |

|

|

Inside diameter of delivering pipe |

mm |

Ф125 |

|

|

Dimensions:length×width×height |

mm |

6000x2300x3150 |

|

|

Total weight |

kg |

6000 |

|

|

The biggest transportation is away from vertically (/Level) |

m |

150/600 |

The Technical Parameters of Diesel power concrete pump with mixer :

| Model | DJBT30 | DJBT40 | DJBT50 |

| Main oil pump | Kawasaki 112mlr | Kawasaki 112mlr | Kawasaki 140mlr |

| Concrete transport cyliner | 180*800 | 180*800 | 200*1000 |

| Hydraulic cylinder | 90*800 | 100*800 | 110*1000 |

| Diesel engine | weichai/Cummins | weichai/Cummins | weichai/Cummins |

| Hydraulic valve | Taiwan brand | Taiwan brand | Taiwan brand |

| PLC unit | Siemens | Siemens | Siemens |

| Electric parts | Schneider& Omron | Schneider& Omron | Schneider& Omron |

| Hydrauloic Pipe | Italian Manuli brand | Italian Manuli brand | Italian Manuli brand |

| Capacity(m³/h) | 35 | 38 | 45 |

| Transport height (m) | 50 | 60 | 80 |

| Transport distance (m) | 200 | 250 | 300 |

| Hydraulic pressure(MPA) | 8 | 10 | 11 |

| Rated speed(rpm) | 1800 | 1800 | 2200 |

| Max aggregate(mm) | 35 | 35 | 35 |

| Hopper volume(m³) | 0.5 | 0.5 | 0.5 |

| Loading height(mm) | 1100 | 1100 | 1100 |

| diameter(mm) | ∅125 | ∅125 | ∅125 |

| Concrete collapse (mm) | 160-220 | 160-220 | 160-220 |

| combinatorial size (mm) | 4500*2100*2300 | 4500*2100*2300 | 4500*2100*2300 |

| separate model size(mm) | 5600*2100*2300 | 5600*2100*2300 | 5600*2100*2300 |

| Weight(kg) | 5200 | 5300 | 5500 |

| Mixer model(L) | 450 | 450 | 450 |

| Container | 20ft container | 20ft container | 20ft container |

language

language