JAW CRUSHER

【Output Size】: 15 – 300mm

【Capacity】: 50 – 800T/H

【Crushing materials】: Quartz, granite, basalt, limestone, river stone, sandstone, shale, iron ore, copper ore, gold ore etc.

【Applications】: Widely used in various industries, such as mining, road and railway construction, building construction, water conservation and chemical industry etc.

Jaw crusher is a kind of stone crusher machine which is widely used as primary or secondary crusher in stone crushing plant. The purpose is to reduce hard stone material to a small size that it can be transported by conveyors to the next crushing stages.

What is jaw crusher?

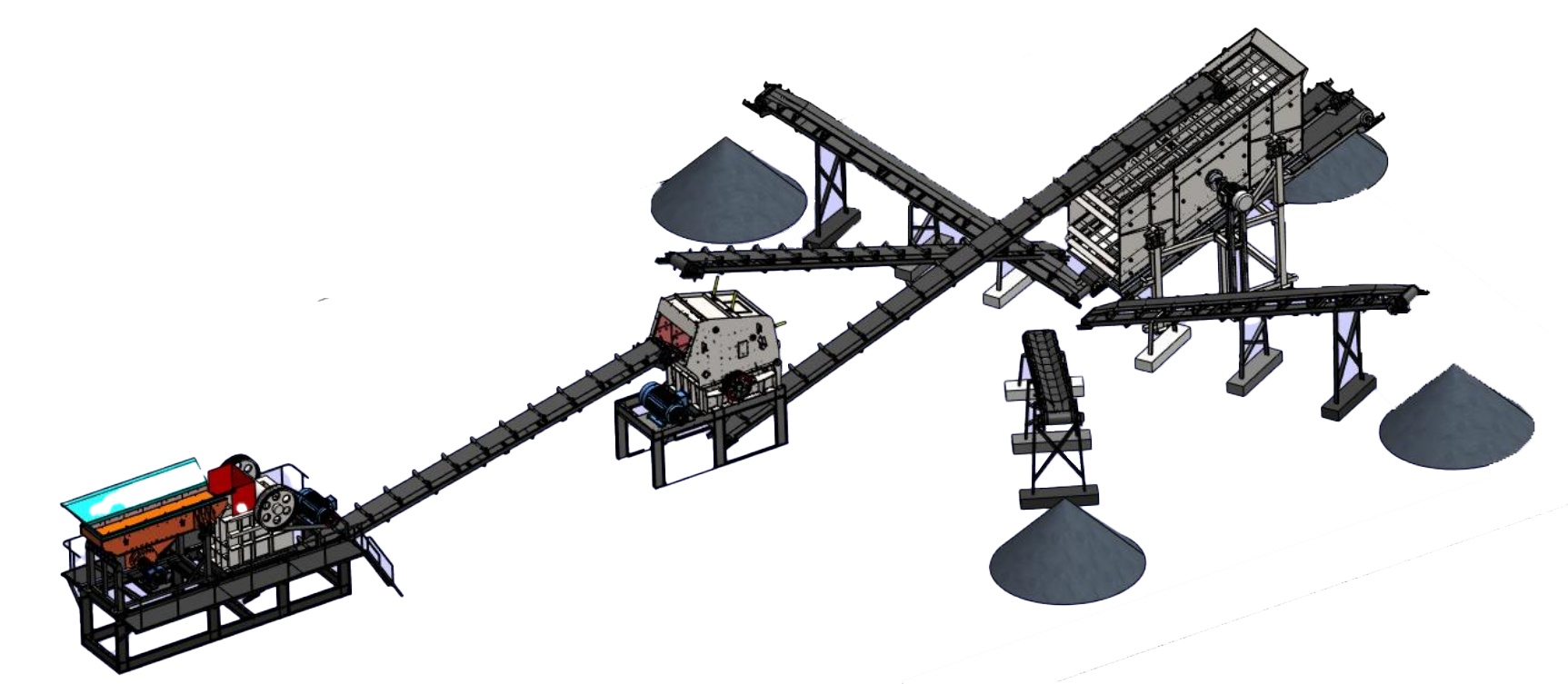

Jaw crusher is a stone crushing equipment with high production capacity, large crushing ratio, and high crushing efficiency. It is mainly used for primary and secondary crushing of hard or medium-hard stones. It can process all kinds of ores with compressive strength not higher than 320MPa to medium particle size at one time. It is often combined with cone crusher, impact crusher, sand making machine, etc. to form a complete set of sand and gravel production plant. PE jaw crusher is widely used in mining, metallurgy, chemical industry, building materials, electric power, water conservancy, transportation and other fields.

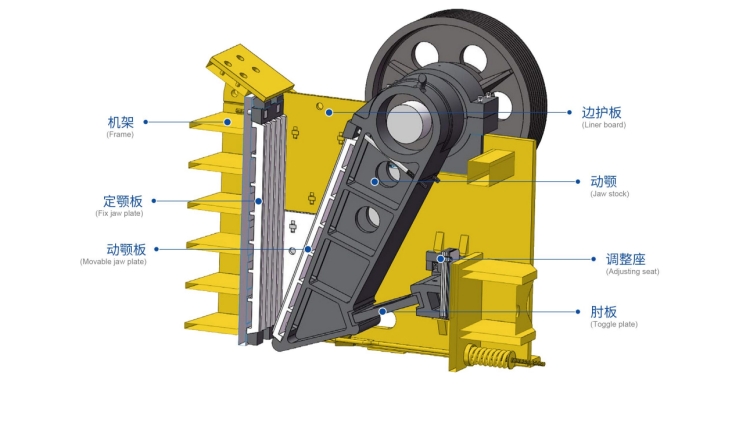

Working principle

Jaw Crusher machine uses compressive force to break hard stone material, such as granite, basalt, limestone, gold ore, boulders etc. There two vertical manganese jaw plates create a V-shaped cavity called crushing chamber, where the top of the crushing chamber is larger than the bottom.

The required rock size is determined by the gap between the jaws.

How to choose jaw crusher machine?

1.Model: Jaw crusher model depends on the size of the feeding port. Choosing suitable model is the main factor that buyers need to consider in the initial stage. The size of the model determines the production capacity range of stone crusher.

2.Feed port size: raw material size determines the size of jaw crusher feeding port. The larger the crushed material, the larger the size of jaw crusher feeding port. Large size stones need to choose a large-sized feed port to meet the production needs, and at the same time avoid troubles caused by inappropriate models.

3.Processing capacity: The processing capacity of jaw crushing machine is a key factor to purchase stone crusher. The output per hour is one of the reference factors. It determines the scale of stone production plant.

4.Motor power: The motor power is determined in combination with the overall size of stone crushers. If the equipment is large and the motor power is too small, it will definitely not be able to carry it. Choosing a reasonable electric power will help improve the production efficiency of jaw crusher.

If you are a beginner and do not know how to choose a suit jaw crusher , tell us your raw material characteristics, finished product requirements, site conditions, production budget, hourly production, and other requirements, we have professional engineers to equip you with a suitable model at a reasonable price. Next, let's see the types of jaw crusher we can supply. Learn more about each jaw crusher specification and application.

Specification

PE series jaw crusher

Feeder Opening

Size(mm)

Max. Feeding

Size (mm)

Outlet adjusting

Size(mm)

Capacity

(t/h)

Motor Power

(kw)

Overall Dimension

(mm)

Model

PE250x400

250x400

210

25-60

5-20

15

1215x1240x1210

PE400x600

400x600

350

40-90

15-60

30

1700x1750x1680

PE500x750

500x750

425

50-100

40-130

45

2150x1900x1950

PE600x900

600x900

500

60-125

90-180

55

2500x2010x2350

PE750x1060

750x1060

630

60-150

110-380

110

2630x2310x3110

PE900x1200

900x1200

750

95-165

220-450

132

3720x2850x3250

PE1000x1200

1000x1200

850

200-300

280-560

160

3820x2850x3250

PE1200x1500

1200x1500

1020

150-300

400-800

220

4590×3342×3553

PE1500x1800

1500x1800

1200

210-360

520-1100

280

5100x4700x4300

PEX series jaw crusher ( Fine jaw crusher , suit for small size rock stone and crush the stone size more smaller than PE Series Jaw crusher )

| Model |

Feeder Opening Size(mm) |

Max. Feeding Size (mm) |

Outlet adjusting Size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall Dimension (mm) |

| PEX150x750 | 150x750 | 120 | 10-40 | 5-16 | 15 | 1310x1118x1145 |

| PEX250x750 | 250x750 | 210 | 15-50 | 15-30 | 22 | 1440x1751x1515 |

| PEX250x1000 | 250x1000 | 210 | 15-60 | 15-52 | 30 | 1730x1950x1400 |

| PEX250x1200 | 250x1200 | 210 | 15-60 | 20-60 | 37 | 1730x2150x1400 |

| PEX300x1300 | 300x1300 | 250 | 25-60 | 30-105 | 55 | 2000x2320x1730 |

*The output will vary according to different materials, feed particle size and other factors !

language

language